Technology

Our technology allows us to offer municipalities and waste management companies the cleanest and most economical MSW treatment solution commercially available.

Blue Arrow’s technology, developed and patented by Fulcrum and licensed to Blue Arrow, reduces by up to 80% the amount of municipal solid waste (MSW) that reaches landfills, thus preventing the release of methane, a harmful greenhouse gas (GHG) into the atmosphere. Blue Arrow’s plants will each process up to 1 million tons of MSW per year, thus avoiding the release of over 1,300,000 tons of CO2-equivalent into the atmosphere for each Blue Arrow plant. Because we convert waste to a low carbon synthesis crude that we sell as a decarbonization additive to be refined into SAF, we are able to provide this benefit at no cost to municipalities.

Process

Fulcrum’s patented process integrates three technologies that have been operating for decades to form an integrated continuous process:

Feedstock Processing Facility

This plant separates and converts thousands of tons per day of household garbage into a feedstock material prepared for gasification. The resulting feedstock consists of one-inch square, lightweight pieces of carbon-rich material that together comprises a fluff.

We take waste that is otherwise destined for landfills and has already gone through formal and informal recycling processes. Untreated MSW emits massive amounts of methane and is therefore one of the world’s largest most damaging sources of greenhouse gas emissions. We substantially reduce these emissions by taking everything from the carbon chain. We also save money for municipalities or waste haulers by reducing their landfill costs and by extending useful lives of their landfills.

The feedstock processing facility at Fulcrum’s Reno, Nevada plant has been operating on a commercial scale since the end of 2016 and has been successfully producing this feedstock under the necessary technical requirements for several years.

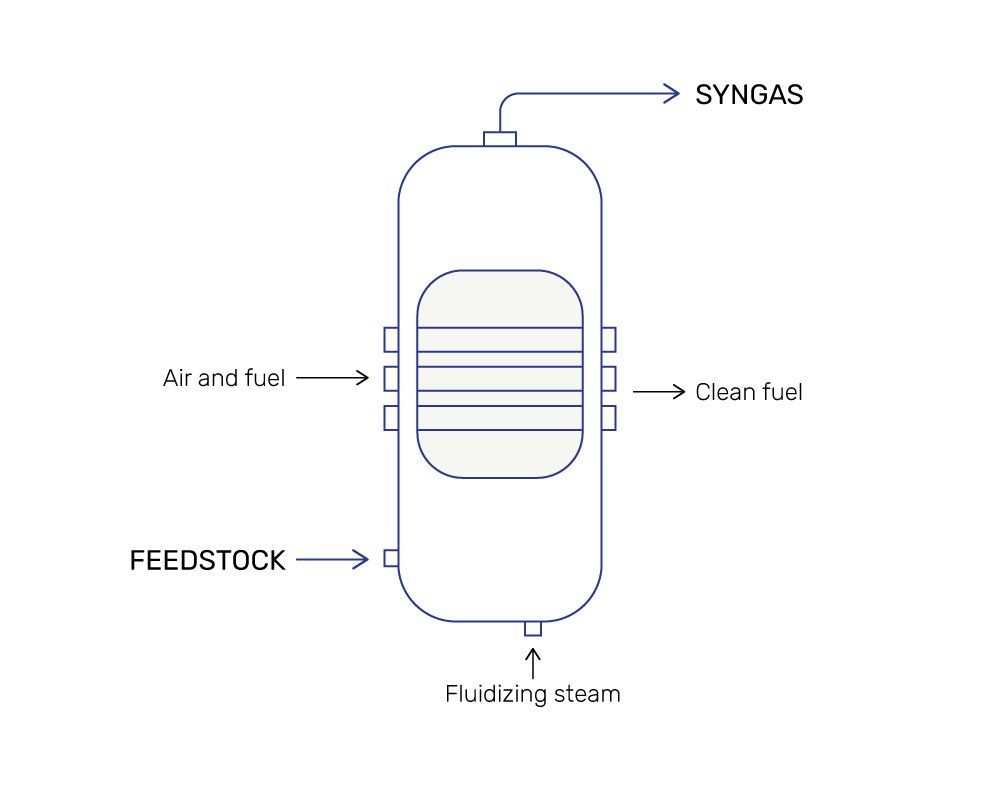

Gasification

The gasifier converts the prepared feedstock into a synthetic gas (syngas) of simple molecules of primarily carbon monoxide and hydrogen, using pressure, steam and high temperatures. The syngas is then cleaned and compressed to feed the Fischer-Tropsch process as described below.

Our gasification process does not incinerate MSW, and therefore the process generates close to zero emissions. The heat collection system cools the syngas and feeds energy to the plant, recycling the heat, improving the process efficiency and saving energy. There are no toxic ash, dioxins, or furans produced in the process.

Similar gasification technology has been operating on a commercial scale for over 75 years but only our process creates syngas suitable for Fischer-Tropsch liquid fuel from MSW at commercial scale. Fulcrum is successfully gasifying MSW at its Reno, NV facility today.

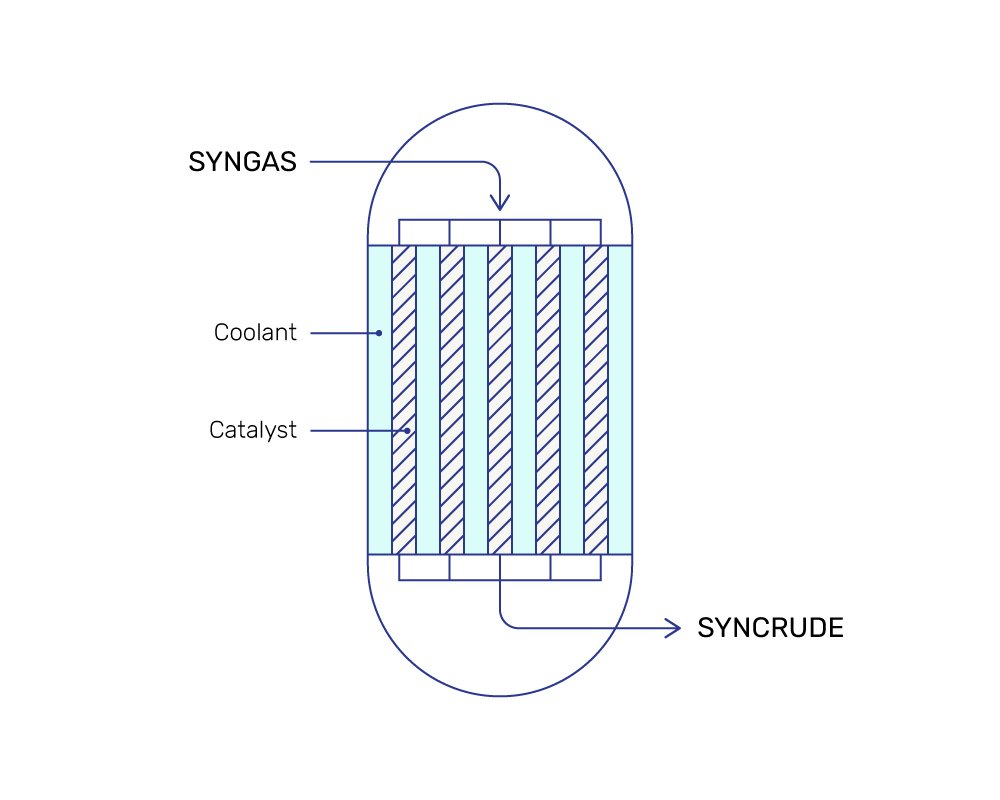

Conversion to Fischer-Tropsch Liquids

The Fischer-Tropsch process uses a proprietary catalyst to convert Syngas into Synthesis Crude (syncrude), which is then sent to a refinery to be upgraded into transportation fuel. This catalyst forms carbon and hydrogen chains from the synthesis gas produced by the gasifier to form a fuel that is highly desirable for refineries given its chemical and environmental attributes.

The resulting product represents the highest possible energy value from MSW as the energy captured in the process is significantly more efficient than any other alternative such as electricity to be sold uneconomically, or coal-alternatives to be incinerated. Syncrude can be transported worldwide and upgraded to clean fuel where it is needed most: jet airplanes that have no electric or other alternatives to traditional fuel.

This technology has been used on a commercial scale for more than 80 years and is commonly used for natural gas and coal. It is a simple chemical reaction that condenses the gas as it passes through a catalyst, which requires minimal energy and helps make the process extremely clean.

The entire process consists of commercially available technologies and processes that have been in operation for decades.

Fulcrum and Blue Arrow integrate them into a unique and patented process that offers compelling economic and environmental solutions for municipalities concerned with waste management. At the same time, we produce extremely low carbon Sustainable Aviation Fuel at commercial scale to help decarbonize the airline industry.